Please wait while we gather your results.

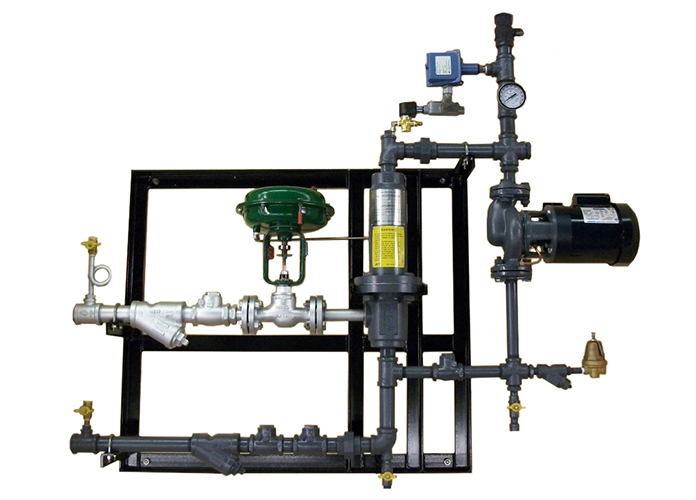

Variable Flow Steam Injection Heater

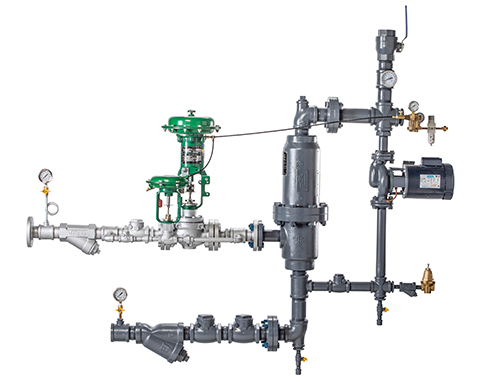

Pick Large Capacity Variable Flow Heater in Carbon Steel

Pick Variable Flow Heater with all 316 SS Wetted Parts

Pick Model 6X50 Variable Flow Heater

Pick Carbon Steel Flanged Variable Flow Heater

Pick Variable Flow Heater with all 316 SS Wetted Parts on 304 SS Frame

Pick Large Capacity Variable Flow Heater with Dual Steam Control Valves

Pick Model 6X10 Variable Flow Heater on Wall Mount Frame

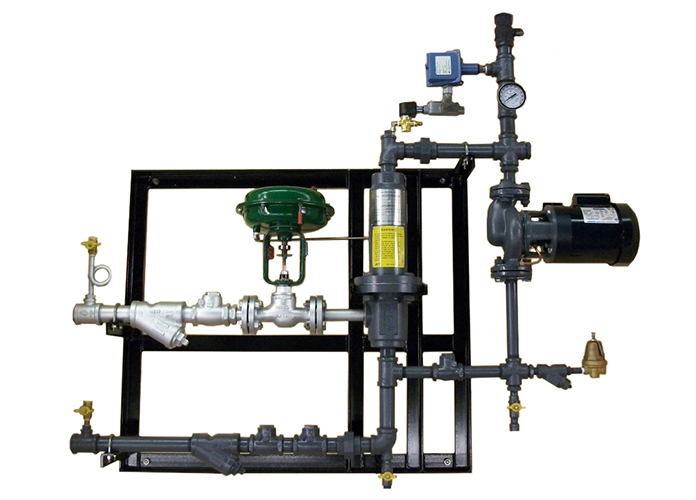

Variable Flow Steam Injection Heater

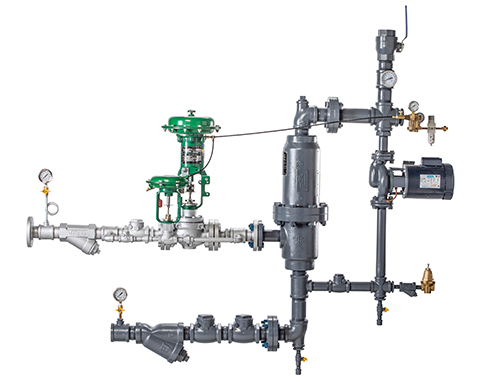

Pick Large Capacity Variable Flow Heater in Carbon Steel

Pick Variable Flow Heater with all 316 SS Wetted Parts

Pick Model 6X50 Variable Flow Heater

Pick Carbon Steel Flanged Variable Flow Heater

Pick Variable Flow Heater with all 316 SS Wetted Parts on 304 SS Frame

Pick Large Capacity Variable Flow Heater with Dual Steam Control Valves

Pick Model 6X10 Variable Flow Heater on Wall Mount Frame